PASSIONATE PEOPLE

MANUFACTURING SOLUTIONS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Nationwide Service

Request a Quote

Industrial Blade Management Made Easy

- Vendor Managed Inventory - Guaranteed Monthly Program Pricing- Pickup and Delivery- Operator Training- Manufactured Best-in-Class Slitting Tools- Winder Shutdown Assistance

SLITTER MANAGEMENT PROGRAM

Are slit edge or quality issues driving up costs? Scrap or returned products causing concerns? Or inexperienced staff or injuries causing inefficiency? It may be time to optimize your slitting operation with professional blade management.

The Valley Grinding & Manufacturing Slitter Management Program can improve operator confidence and slitting processes while reducing your administrative costs.

HOW PROFESSIONAL BLADE MANAGEMENT WORKS

Share your needs. Our team will listen, and then design a program around your requirements, needs and budget. And we provide on-site services to ensure the mechanical integrity of your slitter sections as part of the packaged price.

Our goal? Optimize your slitting operation by managing your slitting process and tooling.

Here’s why you can expect more savings and improved efficiency for your entire facility.

1. Guaranteed monthly program pricing

- Cover individual assets or entire mills

- Reduce purchasing and storeroom touches

- Stay budget-friendly

- Receive technical and engineering support

2. Staff training

Winder Operator Training is offered per facility schedule to include all winder operators. Operators are trained on the principles of shear slitting, how the slitter section is designed to work and what they can look for in upset conditions to correct the slit edge.

Access a full training guide on the principles of shear slitting to learn more here.

3. Manufactured best-in-class “A11 and Carbide” slitting tools

- Made in Little Chute, Wisconsin

- U.S. steel

4. Winder shutdown assistance

- Slitter section audits—mechanical inspection of the slitter section with report

- Product installation (Valley Grinding super-finished knives), if requested

5. Super-finisher sharpening machines

- Valley Grinding manufactures its own sharpening machines for optimal blade sharpening services

- Providing the most consistent, high-polished, keenest edges in the industry

6. Vendor managed inventory

- Automatic replacement one-for-one when minimum outside diameters are met

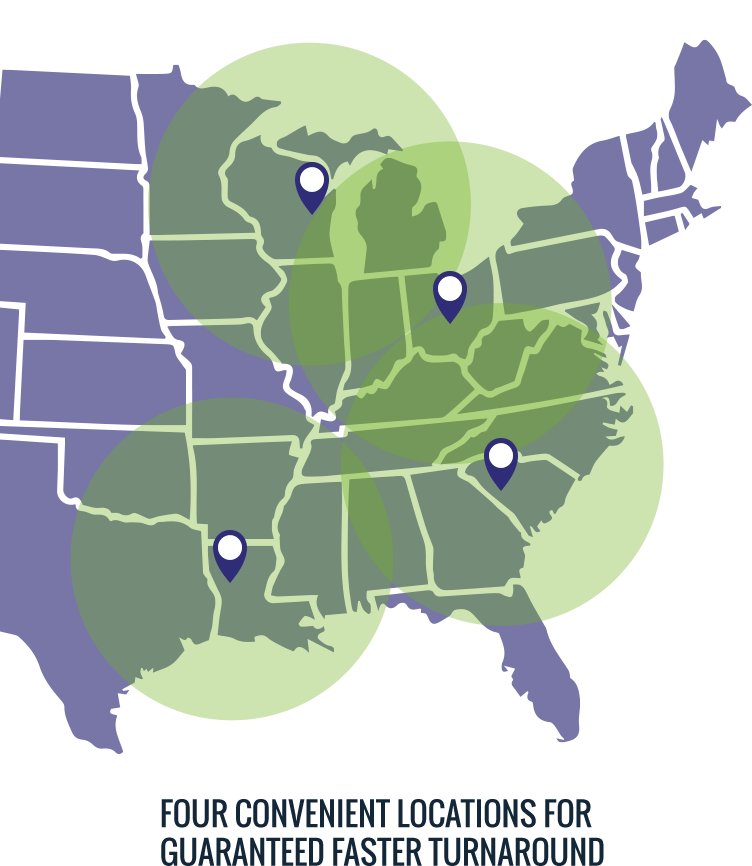

7. Pickup and delivery

service at four regional locations (WI, OH, SC and LA)

- Emergency sharpening service

- Experienced, safe, courteous drivers who are safety certified

- Newer-year vehicles are brand visible and GPS tracked, keeping your assets safe to and from our service centers

8. Custom aluminum or wood shipping boxes

- Top/bottom slitters and sheeters at each machine

- Improve organization and asset tracking at the machine

9. Protective blade edge coating

- Reduce the chance of premature blade damage during transportation and enhance employee safety

10. ISNetworld® and TAPPISAFE® members

Call for a Free Quote

Nationwide delivery available

(800) 950-7675

(800) 950-7675

Shop Our Parts Online

Visit our new online store to purchase today.

Shop

READY FOR PROFESSIONAL BLADE MANAGEMENT?

See a difference in the way things are cut with industrial blade management. Contact us today and we’ll get back to you within one business day.

Need blades? Buy easily at our online store: advantedgesupply.com. For immediate assistance, please call (800) 950-7675.

Thank you, your information has been submitted and we will contact you shortly. If you seek immediate attention please call (800) 950-7675.

Valley Grinding & Manufacturing

Oops, there was an error sending your message.

Please try again later.

Please try again later.

WISCONSIN

,

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

HOURS

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

CONTACT US

This is a placeholder for the Yext Knolwedge Tags. This message will not appear on the live site, but only within the editor. The Yext Knowledge Tags are successfully installed and will be added to the website.

Rebuild, Repair, Recondition, Retool

Privacy Policy

| Do Not Share My Information

| Conditions of Use

| Notice and Take Down Policy

| Website Accessibility Policy

© 2025

The content on this website is owned by us and our licensors. Do not copy any content (including images) without our consent.

Share On: